The world of construction and technology is advancing at a rapid pace achieving what no-one thought possible only a few years ago. A split-pylon concept bridge is the focus of an EPSRC-funded project at Sheffield and Brunel University. Partnering with a long span bridge expert, Ian Firth, the team of UK engineers used mathematical modelling techniques to identify new bridge designs. They claim that it could beat the current record of a 2 km single span bridge.

Newly identified bridge structures could allow for the construction of significantly longer bridges in the near future. The possibility to make a crossing over the Strait of Gibraltar, from the Iberian Peninsula to Morocco is very real. You can find the new research in the Proceedings of the Royal Society which was published on 19 September 2018.

Bridge Research And Development

The exciting research project identified bridge concepts that require fewer construction materials to create longer bridge spans. Pulling out all the stops, the team looked at a theory from famed British engineer Davies Gilbert. Gilbert used mathematical theory in the early 19th century to recommend new optimal shapes for cables following a ‘catenary of equal stress’. A catenary is the curve of a hanging chain or cable under its own weight, supported only at the ends.

A span of a bridge is the distance of suspended roadway between towers. The current world record is just under 2 km with the most popular form being the suspension bridge form. It is used for the Humber Bridge (cable-stayed bridge form) where cables directly connect the tower to the roadway. The recently constructed Queensferry Crossing in Scotland is a prime example and it’s becoming increasingly popular.

As bridges become longer, a bigger portion of the structure has to carry the bridge’s own weight before even considering the traffic crossing it. Thus, a small increase in length requires significantly more material which means a heavier structure needing even more supporting material. It also sets a limit on total bridge span as, beyond this limit, a bridge cannot support its own weight.

Of course, they could use stronger and lighter materials but steel remains the preferred choice and for good reason. Steel is tough, readily available and relatively cheap which means the only way to increase span is changing the design.

Split-Pylon: The Future Of Bridge Construction

According to Professor Matthew Gilbert from the University of Sheffield, “The suspension bridge has been around for hundreds of years and while we’ve been able to build longer spans through incremental improvements, we’ve never stopped to look to see if it’s actually the best form to use. Our research has shown that more structurally efficient forms do exist, which might open the door to significantly longer bridge spans in the future.”

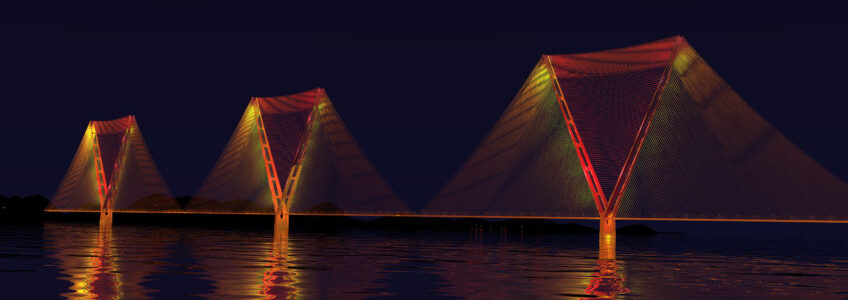

The new bridge design contains regions resembling a bicycle wheel with multiple ‘spokes’ instead of a single tower. While mathematically optimal, these are very difficult to build on a large scale. Instead, the team replaced these with split towers consisting only of two or three ‘spokes’. As a result, it retains most of the optimal design benefits with a slightly easier construction process.

“Very often there are slight variations on [the mathematically optimal] forms, which are only very slightly less efficient, in that there is very little extra weight, but they are much easier to build,” said Gilbert.

To cross the Strait of Gibraltar covering 14 km, they would need 5 km spans. A traditional suspension bridge design would require much more material which makes it at least 73% heavier than the optimal design. In comparison, the two- and three-spoke designs would only be 12 and 6% heavier. This could make long-span bridge construction much more economical.

The new bridge forms require less material mainly as a result of transmitting the forces from the deck more efficiently through the bridge superstructure and into the foundations. This form of bridge construction works as it keeps the load paths short, avoids sharp corners between tensile and compressive elements.

What Comes Next?

The team emphasised that their research is just the beginning and they need to conduct further research and development. Their concepts are not ready yet for immediate construction of a mega span bridge. At the moment, the current model only considers gravity loads and hasn’t taken into consideration dynamic forces from traffic or wind loading. They also need to do more work to address construction and maintenance issues.

“We haven’t yet looked at the lateral loading from wind,” Gilbert said. “So we’d like to work with experts in that field, to see whether [the design] is a practical solution for very long spans.”

Whatever the outcome, the future of bridge construction looks promising. Can you imagine the impact of a long-span bridge between Europe and Africa on trade and travel?

For more interesting articles on structural steel, fabrication, advanced manufacturing and precision engineering, visit our blog site. You can also find us on social media or get in touch with if you require any assistance with your project. PRV Engineering manufacture for a wide range of industries including automotive, aerospace, defence and rail among others.

Recent Comments