With a global housing crisis and a scarcity of skilled labour, new methods are emerging to streamline construction and bring affordable housing to areas in need. One solution making waves in the construction sector is mobile micro-factories for affordable housing. This innovative technology promises to address the shortage by enabling on-site manufacturing for housing components, reducing costs, and minimising the demand for skilled labour. While PRV Engineering is not involved in this specific technology, our expertise in structural steel fabrication and site work aligns with forward-thinking solutions that transform the construction landscape.

What Are Mobile Micro-Factories?

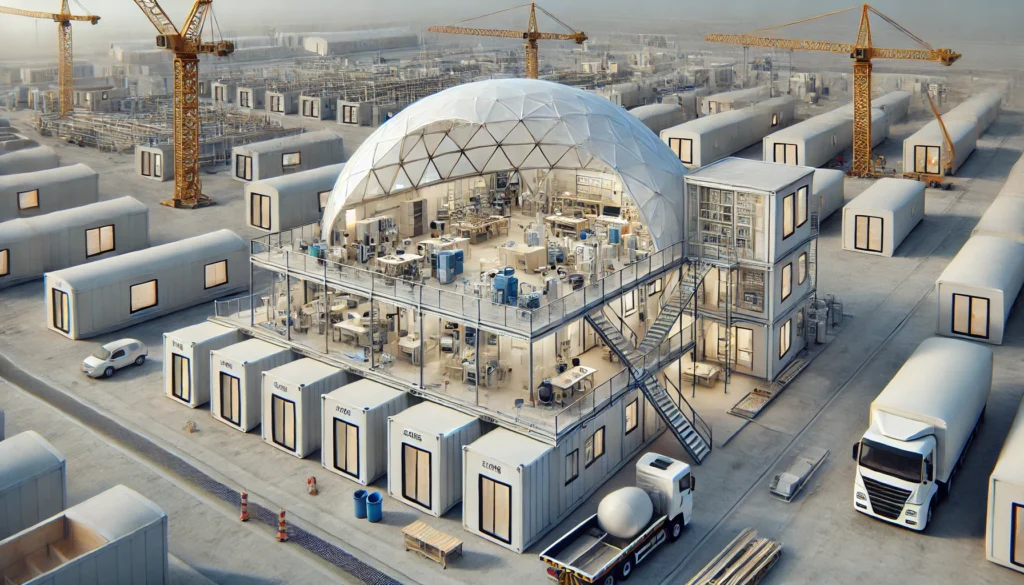

Mobile micro-factories, as developed by companies like Cuby, are small, transportable manufacturing facilities that produce various building components directly at the construction site. At just 30,000 square feet, these factories are equipped with advanced hardware and software to fabricate everything from windows and doors to kitchen cabinets. By producing parts on-site, mobile micro-factories significantly reduce the logistics, costs, and time associated with traditional supply chains in the housing industry.

Each mobile micro-factory operates as a modular unit that can be relocated and quickly set up wherever housing projects are planned. This flexibility enables construction teams to generate the necessary components on demand, streamlining the process and minimising delays. The output is impressive; mobile micro-factories can produce an entire home within a single day, ready for assembly.

Recommended: Why Should Developers Consider Modern Methods of Construction?

Addressing Skilled Labour Shortages in Construction

The construction sector in the UK, US, and other parts of the world is increasingly affected by a skilled labour shortage. A recent survey found that around 88% of US contractors struggled to fill positions requiring specific trade skills, while the UK faces a similar challenge. This scarcity is expected to worsen as nearly 40% of the US workforce retires over the next decade, creating a need for alternative methods to maintain housing production levels.

Mobile micro-factories for affordable housing play a critical role here. Since these units automate much of the component production, they reduce the reliance on highly skilled tradespeople. Instead, fewer, unskilled workers can be trained to operate the factory’s technology, achieving faster results without sacrificing quality. In fact, Cuby claims that just four unskilled workers on two shifts can fully assemble a house within 30 days.

How Mobile Micro-Factories Work

At the heart of this innovation is a highly organised, automated process that can operate independently once established. Each mobile micro-factory is equipped with the necessary technology to produce custom home components that meet specific building codes and regulations. Components are produced in kits and sent to the assembly area on-site, where they are put together to create a finished structure.

One major advantage of on-site manufacturing for housing is the level of customisation it allows. Mobile micro-factories can adapt their output based on the requirements of the area, ensuring compliance with local building codes and zoning laws. This adaptability is crucial for implementing mobile micro-factories in different regions and markets.

Key Benefits of Mobile Micro-Factories for Affordable Housing

Cost Savings

Based on early projections or specific company-reported data rather than industry-wide benchmarks, in the US, the average cost to build a mid-market home is around $200 per square foot. With mobile micro-factories for affordable housing, companies like Cuby reduce this cost to roughly $100 per square foot. This approach makes new homes more accessible to a wider population, providing a feasible solution to meet the increasing demand for affordable housing.

Time Efficiency

Time is another significant benefit. Traditional home building is subject to numerous delays due to weather, labour availability, and supply chain issues. With a mobile micro-factory on-site, components are produced as needed, enabling rapid assembly and reducing the time required to build a home from several months to just 30 days.

Environmental Sustainability

With efficiency comes sustainability. Mobile micro-factories contribute to a reduction in transportation emissions and construction waste, cutting CO₂ emissions by 2.2 million tons across Cuby’s projected 275 micro-factories in North America, Europe, and Australia. Waste reduction is a core part of their approach, with an estimated 755,000 tons of construction materials saved.

Global Scalability and Implementation

Mobile micro-factories for affordable housing have immense potential in global markets, including the UK, Canada, Europe, and Australia, where housing shortages and labour challenges mirror those in the US. Cuby’s COO, Aleksandr Gampel, has announced plans to deploy over 275 micro-factories internationally, with the goal of creating 200,000 homes and over 100,000 jobs while simultaneously reducing waste and emissions.

To implement mobile micro-factories effectively, companies must consider local building regulations, zoning laws, and housing requirements. These micro-factories can adjust their production processes to meet local demands, allowing governments and construction firms in various countries to adopt the technology with minimal friction.

In the UK, this technology offers a direct response to the critical shortage of affordable housing, providing a sustainable and efficient construction method that minimises both environmental impact and labour requirements. This adaptability makes on-site manufacturing for housing a practical solution for addressing housing challenges across the world.

Embracing Innovation in the Future of Construction

The promise of mobile micro-factories for affordable housing is undeniable. By drastically reducing costs, dependence on skilled labour, and construction time, this innovation represents a significant shift in how the construction industry can respond to the global housing crisis. Though PRV Engineering is not currently involved in mobile micro-factories, our work in structural and architectural steel fabrication and construction services aligns with industry trends towards efficiency and sustainability in building practices.

As technology continues to evolve, solutions like mobile micro-factories and modular construction are shaping the future of affordable housing, offering a more efficient, environmentally friendly approach to meet the ever-growing demand.

Recent Comments