Think of structural steel framed buildings and the sort of things that come to mind are probably, office sky scraper buildings or big warehouses and agricultural buildings. The sorts of thing you see in big cities or on the outskirts when new out of town shopping malls go up. But steel framed structures are commonly used across a whole range of construction projects; garages, residential housing and short term temporary structures all make good use of steel frame construction methods because they are durable, flexible, cost effective and sustainable.

About prvengineering

- Email: Rob.thomas@wsi-emarketing.com

- Nice Name: prvengineering

- Website: https://www.prv-engineering.co.uk

- Registered On :2024-09-18 08:23:17

- Logged in as: prvengineering

prvengineering Posts

Back in March this year London was set to see the introduction of 5 all electric double decker buses capable of driving up to 190 miles in day on one 4 hour overnight charge. The 5 buses joined a fleet of single deck electric, hydrogen and hybrid buses as part of the effort to reduce emissions in the city centre.

At the other end of the country Stagecoach are operating all electric bus services in Inverness and having worked with manufacturer Optare have managed to extend the range of miles the vehicles can do. In addition to running on electricity, these buses also feature electric heating systems rather than the standard diesel ones. This makes them the UKs’ most efficient electric buses in terms of kWh per mile and they fist of their kind.

Even though waterjet cutting has only come into its own in recent years it may surprise you to know that it has been around since the 1930s. At that time it was used at a low pressure and only for cutting soft materials. Whilst things continued to develop after the war, waterjet cutting became much more effective in the 1970s, when the first reliable high pressure pump was developed.

Whilst the earlier waterjet machines could cut softer materials they could not handle harder materials and metals. The ability to cut harder materials like metal came about following the addition of an abrasive to the waterjet cutting nozzle. This was a technique first used in the 1930s, however early versions of the nozzle were not commercially viable. Further development of the nozzle and the availability of a reliable pump led to a more effective waterjet that could now cut through a bigger variety of materials.

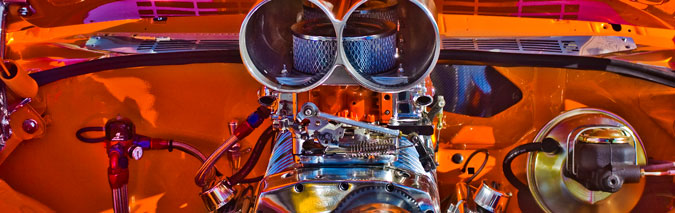

When we think of the technical developments in F1 and motorsport generally, we can all probably think of an area in the automotive industry where those developments have had an impact. But do you ever think about what or who else benefits of those developments?

If I was to say that the care of premature babies has been impacted by motorsport technical developments you’d probably wonder how. What about supermarkets? How could they possibly benefit from the motorsport industry?

These are only a couple of examples of where motorsport innovation is being used to solve challenges in other industrial sectors.

Whilst the weather may have put a premature end to the day on Monday, the Farnborough International Air Show is back on track with attendance and business at the trade show thriving.

Statistics earlier in the year were predicting one of the most successful shows yet with increased numbers of international participants in the trade show and conferences, and more dedicated country pavilions. In addition to first time country pavilions for Austria, Brazil, Republic of Ireland and China, Boeing has a special pavilion celebrating their centenary which falls on the Friday of the show.

The show has become the UK’s shop window for all things aviation from the civilian, defence and space sectors

One month on from our last post about Bloodhound, the date for the first record attempt has been set. October 2017 will see the first land speed record attempt for 20 years.

The signing of a major deal means that the project has now secured funding to complete the car and start preparing for their testing in South Africa next year.

When Bloodhound went on display in 2015 it was as a trial build and without fluids. This was done to make sure that the 35,000 individual and bespoke parts actually fitted together. Brackets were checked to see if they were in the right places leaving enough room for service and maintenance activity as well as checking the tolerance of manufactured parts.

There are many advantages of waterjet cutting compared to other methods, but if we had to try and summarise them neatly into a few words we’d say;

The ability to cold cut almost any material in any direction with less waste and a superior finish.

But really that’s not enough of an explanation, so let’s expand a little on that statement and address some of the areas of improvement over more traditional cutting methods.

Omni-directional cutting

Waterjet cutting allows omni-directional cutting – the ability to cut in any direction which gives much greater cutting flexibility. In most cases starting holes are not required as the water jet is able to perforate the material. It is now much easier to cut more complex shapes and designs into all sorts of materials.

Solar Impulse 2 left New York on Monday 20th June and landed in Seville, Spain on 23rd June at 7.30 am. The total flight time was 71 hours and 8 minutes and now means that the aircraft has crossed both the Pacific and Atlantic oceans.

Solar Impulse 2 is attempting the first renewably powered circumnavigation of the globe and is now nearing the end of its 35,000km journey. The trip started in July 2015 and will finish back at the starting point in Abu Dhabi. The immediate next steps are to negotiate a route back to Abu Dhabi via Egypt or Greece.

Solar Impulse 2 has a wingspan of 72m and weighs more than 2 tons. It is powered by more than 17000 solar cells and achieves an average speed of 75 km/h.

Just like the Bloodhound project, the Solar Impulse 2 team are providing an educational platform around their project, giving resources to schools and universities as well as providing opportunities for live hangouts with members of the team.

Recent Comments