Space Exploration – Beyond Imagination

We are in a race for space travel once again and through the imagination of movie producers and the real advancements in technology, we are all hooked. Movies like Star Trek, Star Wars and a few others did a great job at capturing our feelings and imagination. Even though it may have been science fiction, it’s the sheer possibility of space exploration that drives our love of astronomy and our desire to learn more.

Space is not infinite and somehow there must be an end to it. But if there is, nobody on Earth has figured out where it is, at least not yet. The only thing that has brought us to “the end of the universe” is our limited ability to see deeper into space.

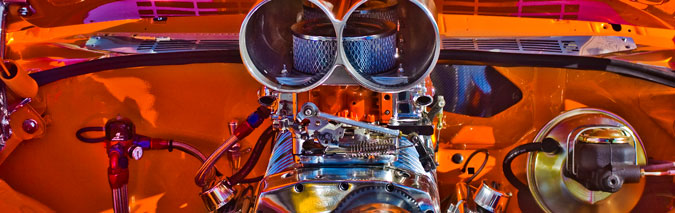

We are getting closer though with advances in technology and propulsion like

Recent Comments