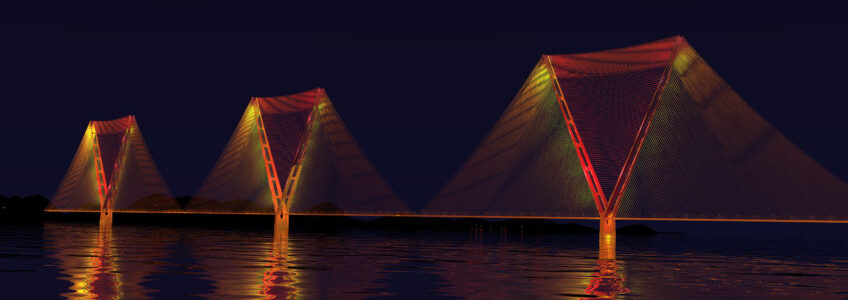

Img credit: sputniknews.com

The defence sector is forever changing and Russia’s new Peresvet laser weapon gives a terrifying glimpse into the future. Russia announced the launch amidst some controversy after the US threatened to withdraw from an arms treaty between the two military powerhouses. Could this be a coincidence? Many people think not. Chances are that it probably fits perfectly with Russia’s plans as tensions between the two countries have increased in recent times.

President Vladimir Putin already promised to deploy several high-tech weapons in the near future when he made his annual address to Russia’s Federal Assembly in March 2018. He wants the West to know that Russia is developing new weapons and should be considered a real force if a New Cold War erupts.

Recent Comments