Steel framework fabrication plays a vital role in modern UK construction, enabling the creation of durable, bespoke structures that meet today’s demands for sustainability and cost control. With over two decades of expertise in steelwork, PRV Engineering has expanded its services to include comprehensive steel framework fabrication, concrete supply, and on-site installation. Designed to support sustainable construction practices and provide clients with greater control over project costs, PRV’s offerings cater to a wide range of architectural and structural needs, from custom platforms to large-scale frameworks.

The construction industry has evolved significantly with many new and improved methods such as structural steel fabrication. This process, along with welding, is demanding and you should only consult experienced fabricators as it requires expert knowledge, skills and resources.

For a successful project, from manufacturing structural steel beams and steel balustrades to components and equipment, every good fabricator should follow a specific process. A less experienced company may not be able to perform the necessary tasks which could compromise product viability.

The construction industry has evolved significantly and with it, many new and improved methods including steel fabrication. If you think about skyscrapers, warehouses and shopping malls, almost every aspect in construction consists of structural steel. Steel framed structures are common across many construction projects including garages, residential properties and short-term temporary structures.

Steel fabrication is used to create various components and products with different qualities for different applications. Fact is, structural steelwork has been the primary choice for most builders, engineers, contractors and structural steel fabricators. Many industries rely on steel fabrication because of the quality, reliability, flexibility, cost effectiveness and sustainability that it offers.

Structural steel fabrication involves a complex process of turning steel into fabricated products for a construction project or other industrial applications. Structural steel has been a first choice in all types of construction and for quite some time. Even the smallest project incorporates steel because it offers faster construction among many other benefits.

The structural steel fabrication and welding process is demanding and you should only consult experienced fabricators. A less experienced company may not be able to properly perform the tasks at hand which means they could compromise the product viability. Welding and fabricating structural steel requires special expertise that only a few companies share, PRV Engineering is right up there.

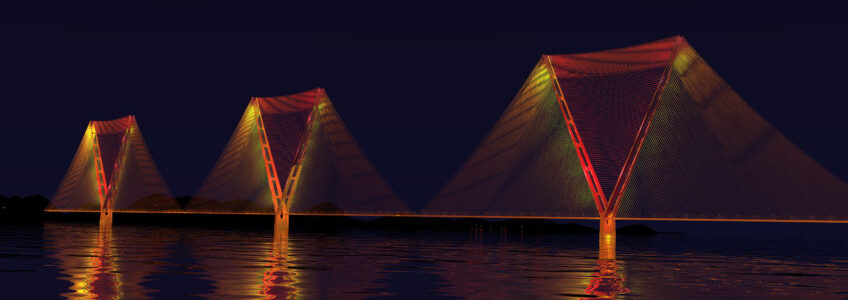

The world of construction and technology is advancing at a rapid pace achieving what no-one thought possible only a few years ago. A split-pylon concept bridge is the focus of an EPSRC-funded project at Sheffield and Brunel University. Partnering with a long span bridge expert, Ian Firth, the team of UK engineers used mathematical modelling techniques to identify new bridge designs. They claim that it could beat the current record of a 2 km single span bridge.

Newly identified bridge structures could allow for the construction of significantly longer bridges in the near future. The possibility to make a crossing over the Strait of Gibraltar, from the Iberian Peninsula to Morocco is very real.

The word “fabrication” means to make something from raw material. Steel fabrication is no different and plays an extremely important role in the world’s infrastructure and economy. Practically every aspect of our civilization benefits from some form of fabricated metal. From household appliances to vehicles and parts, our lives would be unrecognisable without carbon steel, stainless steel and aluminium.

Although the construction of steel buildings dates back to the 20th century, they became more popular during World War II. Thereafter, steel buildings expanded significantly once steel became more readily available. Modern technology, machinery and computer aided design software have pushed steel fabrication to the next level as we see it today. Steel fabrication now involves the implementation of various manufacturing processes including bending, cutting, grinding, brazing and welding.

When you think of structural steel fabrication and construction, what comes to mind first? Most construction projects consist of steel frameworks with skyscrapers, warehouses and shopping malls at the top of the list.

Many industries rely on structural steel fabrication because of the unmatched quality, reliability, flexibility, cost effectiveness and sustainability. But what happens when companies use non-compliant suppliers? Did you know that there are potentially over 7000 UK suppliers who are trading illegally?

Construction is a $10 trillion global industry and robots are set to revolutionise the industry by 2020. Productivity in manufacturing, retail and agriculture has grown exponentially since 1945 but it has barely gone up in construction. How will robots be used to increase productivity and if they do, how will it impact the workforce?

The construction sector has advanced and with it, many new and improved methods including the use of structural steel. Nearly everything in construction consists of structural steel with skyscrapers, large warehouses and shopping malls springing to mind. In fact, steel framed structures are commonly used across a wide range of construction projects including garages, residential housing and short-term temporary structures and for good reason.

Steel fabrication is used to create various components and products with different qualities for

- 1

- 2

Recent Comments