Steel framework fabrication plays a vital role in modern UK construction, enabling the creation of durable, bespoke structures that meet today’s demands for sustainability and cost control. With over two decades of expertise in steelwork, PRV Engineering has expanded its services to include comprehensive steel framework fabrication, concrete supply, and on-site installation. Designed to support sustainable construction practices and provide clients with greater control over project costs, PRV’s offerings cater to a wide range of architectural and structural needs, from custom platforms to large-scale frameworks.

The construction industry is a diverse one, with steel being used in many different ways. Architectural steelwork is an essential part of this and falls into two categories: structural steel and non-structural steel. In this article, we take a quick look at the differences, processes and how PRV Engineering works.

Choosing the right materials for a building project can be tricky as there’s much to consider. Looking at the characteristics of aluminium framework and stainless steel it’s easy to see why the decision should not be taken lightly.

Aluminium and stainless steel may have many similarities but it’s what sets them apart that could determine the final decision. Here are the main aspects that you should investigate when planning your construction project.

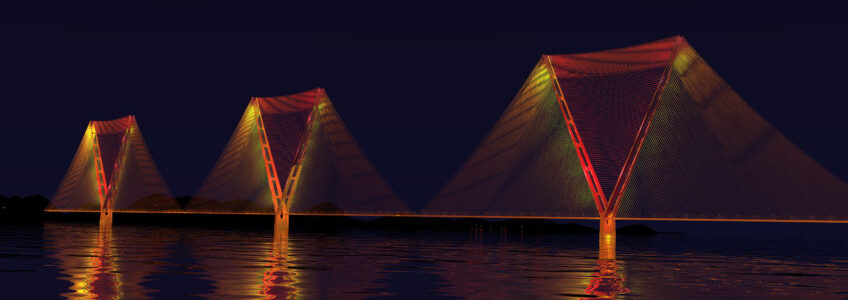

The world of construction and technology is advancing at a rapid pace achieving what no-one thought possible only a few years ago. A split-pylon concept bridge is the focus of an EPSRC-funded project at Sheffield and Brunel University. Partnering with a long span bridge expert, Ian Firth, the team of UK engineers used mathematical modelling techniques to identify new bridge designs. They claim that it could beat the current record of a 2 km single span bridge.

Newly identified bridge structures could allow for the construction of significantly longer bridges in the near future. The possibility to make a crossing over the Strait of Gibraltar, from the Iberian Peninsula to Morocco is very real.

Eindhoven in the Netherlands is set to become the center of attention with 3D printed homes. A bridge has already been constructed using cutting edge technology and now, a total of five 3D printed homes will add to the collection. It comes courtesy of a collaboration between the Technical University of Eindhoven, the Eindhoven municipality and several other firms.

3D printing has been the talking point for quite some time and now, the construction industry is taking full advantage. Additive manufacturing is fast becoming a great asset across various sectors and thanks to new technology, 3D printed houses are a real possibility. How about building a house in just one day?

We see the benefits of 3D printing in the manufacturing, medical and the fashion industry from prototype to production. With construction in mind and large-scale 3d printers, it is now possible to think about bigger projects. It goes without saying that additive manufacturing is ideal for creating models especially in architecture where models are rendered prior to construction.

The construction industry along with the architectural engineering are possibly two of the toughest marketplaces in the world. Fabrication projects are often both complex and demanding where the final product must have high integrity and capable of withstanding nearly anything. It’s also no secret that modern manufacturing and engineering have changed considerably in recent years. Companies now find themselves under pressure to rapidly introduce new products, adapt to local market conditions and improve quality, cost and efficiency.

We can agree that one of the main elements of any fabrication project is cost. And by cost, we refer to

Recent Comments