Mould tooling is a vital aspect of plastic manufacturing, and while the initial cost of producing the tool can be substantial, the economies of scale make it worth the investment. However, it’s still essential to avoid unnecessary expenses during the design for manufacturing (DFM) process. In this article, we take a closer look at some of PRV Engineering’s top tips for saving money on mould tooling.

Deep hole drilling machines are metal cutting machine tools that can create very deep and extremely precise holes in just about any metal. Manufacturers relying on deep hole drilling machines can further optimise the process by using tools such as BTA and gun drills. It’s a prominent method in engineering materials and components used across numerous sectors. In this article, we take a quick look at how deep hole drilling machines work, the processes and some of the most common applications.

Machining is a term that refers to a variety of technologies and procedures in the manufacturing field. There are also different types of machining processes and tools, where some are standalone while others are used in conjunction with others. To help simplify what machining is, the processes and the techniques, we’ve compiled this comprehensive guide.

In today’s modern manufacturing world, not too many products are made without CNC machining. This includes the basics like toys, household appliances and machines but also cars, aeroplanes and medical devices among others. CNC machining is incredibly versatile and many industries cannot do without it.

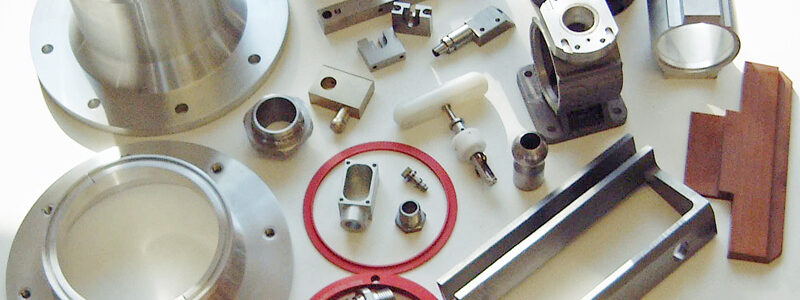

Some of the main industries that rely heavily on CNC machining include aerospace, automotive, medical manufacturing and woodworking. Here, they use it use for various operations such as drilling and routing where the aerospace industry favours CNC machining because it offers the five-axis option when required. This functionality means they can more easily manage hard-to-cut materials such as Inconel.

In healthcare or the medical sector, CNC machining plays an essential role for micro-machining. This involves fabricating all the tiny parts made from different types of materials for various life-saving applications. Examples of CNC machined parts are pacemakers or titanium joints not to mention tools and implements for medical professionals.

In modern-day manufacturing, technology is forever advancing and it is essential to keep up with the all latest trends. Throughout our history, we have seen a number of methods implemented to manufacture custom parts. Today, CNC machining and 3D printing are seen as two of the most widely used manufacturing processes.

With the rapid growth of 3D printing technology, some believe it has become the first choice for many industries. On the other hand, CNC machining is still considered a reliable standard and there really aren’t many things that don’t involve CNC machined parts somewhere in the process.

Looking at the available technologies and industries utilising CNC machining and 3D printing, how do they work? Which industries prefer one or the other and how do they compare?

5-axis machining is now used by many machining companies and allows machining of a part along 5 axes of motion compared to 3 axes in one setup. While this can be a cost saving factor, 5 Axis machining is used more often for complex contour work, which may need simultaneous movement of all 5 Axes.

Recent advances in software have helped make the conversion from 3-axis and 3+2 axis positioning to simultaneous 5-axis machining accessible to everyday numerical control programmers.

Although some of these techniques might require additional programming time, the benefits of reduced machining, setup time and reduced hand-polishing outweigh the costs.

CNC machining or to give it its full title “Computer Numerical Control” machining, allows for increased efficiency through higher levels of automation. In simple terms, the machine and its computer controls to do all the work.

As a result and having taken into consideration their expense and complexity, the machines quickly pay for themselves by reducing the workload and preventing errors. That’s the first advantage of many. CNC machines are widely used in the manufacturing industry with traditional machines, such as vertical millers, centre lathes, shaping machines and routers, having been overtaken.

From metal fabrication and metal removal to Electrical Discharge Machining (EDM), CNC machining has revolutionised just about every aspect of manufacturing processes. The process of Computer Numerical Control or CNC machining involves shaping and fabricating complex three dimensional objects using machine tools controlled by a program running on a computer. The high degree of precision achieved through CNC has increased the demand of such machining services. However, with so many companies claiming to offer unmatched services, it can prove to be difficult to find the right one. In this article we will take a look at various tips to help you find the right CNC machining service.

Recent Comments