Finishing image of industrial spray painting Finishing any engineering job properly is just as important as any other operation along the production cycle. And by finishing the engineering job, we’re not talking about tidying the file and completing the invoicing. We are talking about the paint or powder coating finish to the product

The appearance of a finished product will always have an impact on the saleability. After all, if something looks rough and unfinished it’s less likely to sell. In addition, there’s the safety impact to consider. Rough edges and burrs can not only put buyers off but can be a serious health and safety risk. So an important part of finishing is to remove those risks.

Spray painting was invented in 1892 and whilst it might not require the imagination of Picasso or Constable, it does need a high level of skill to do the job well.

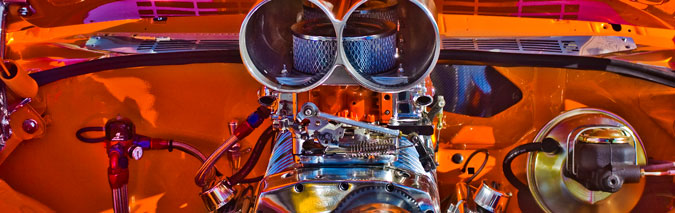

But why do we need to spray paint machines in the industrial sector? Why not just leave the manufactured machines in their original state?

The answer is two-fold. Spray painting not only protects the customers’ machines against rust, but it makes the machines look good!

Six spray painting methods

- Air gun spraying

- HVLP (High Volume Low Pressure)

- LVLP (Low Volume Low Pressure)

- Electrostatic spray painting

- Air assisted airless spray guns

- Airless spray guns

The main variables that industrial spray painters consider when undertaking a job are as follows:

Powder coating is the process of coating a surface in which a powder material is applied using an electrostatic or compressed air method. It is also one of the most advanced techniques for applying a protective and decorative finish to almost any type of metal.

The process of powder coating basically involves spraying an electrostatically charged powder on the surface that needs to be coated. The charged powder particles adhere to the surface, forming a smooth, durable and uniform coating, with a high quality finish.

Many businesses, industries and consumers around the world speak highly of the process which provides one of the most long-lasting, colour durable, economical and high quality finishes. No matter which colour or texture you are looking for, powder coating can provide the right solution.

Metalwork Fabrication at its Very Best from PRV Engineering

Metalwork Fabrication is a skilled, specialist operation, and not one that enough people first associate with PRV Engineering. Maybe that’s because our expertise in other engineering services such a deep hole drilling get more publicity. But here at PRV Engineering, we offer a complete metalwork engineering service that includes the very best in metalwork fabrication.

It might come as some surprise to learn that our metalwork fabrication department regularly turns out a whole range of beautifully finished, fabricated metal products that include:

Finishing with a flourish might sound a little flamboyant. But precision engineering isn’t exactly the sexiest of subjects, so please allow us at PRV Engineering a little leeway, and an opportunity to indulge ourselves!

Finishing any engineering job properly is just as important as any other operation along the production cycle. You’ll have gathered by now that we are talking about engineering finishing rather than simply closing down the job file and archiving it away. No, the sort of finishing that we allude to in this context is painting, both wet paint and electro powder coat.

PRV Engineering have come a long way since our lowly beginnings, when we first set up in 1986 manufacturing tamper proof Lids for the Metal Packaging Industry. We are now one of the leading suppliers of engineering services in Europe, and the journey has been long, and arduous, but ultimately rewarding.

Industries in the manufacturing and heavy machinery sector rely on various specialised techniques for painting surfaces. One of the preferred techniques used today is, of course, spray painting.

We wrote an earlier post on spray painting but today we’d like to talk in a bit more detail about the different types of spray painting techniques available.

- 1

- 2

Recent Comments