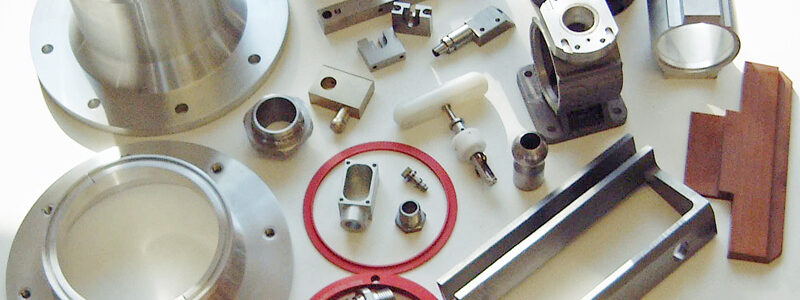

Tool making forms a very important aspect of the manufacturing industry. From designing complex tools to precision engineered machine parts, tool making finds use in a wide range of manufacturing and engineering applications. With improved machining technologies and design capabilities, today it has become easier to produce high performance precision manufactured tools. However, when it comes to choosing a good tool making provider, it can be quite difficult with so many outfits claiming to provide unmatched services. Designing and making precision tools requires a lot of planning, high performance equipment, technical know-how and skill. In this post we will take a look at what things you should look out for when choosing the right tool making service.

When it comes to finishing and cleaning operations, the shot blasting surface treatment technique is a highly effective option. The shot blast technique uses high velocity steel abrasives in a controlled manner (at speeds ranging between 65 and 110 metres per second). This high speed controlled blast creates an abrasive impact which removes surface contaminates, thereby making it an effective method for cleaning iron, steel, forgings, machine parts, fixtures etc. However, before you commission a shot blasting service, there are a few important things you must know about this technique.

From metal fabrication and metal removal to Electrical Discharge Machining (EDM), CNC machining has revolutionised just about every aspect of manufacturing processes. The process of Computer Numerical Control or CNC machining involves shaping and fabricating complex three dimensional objects using machine tools controlled by a program running on a computer. The high degree of precision achieved through CNC has increased the demand of such machining services. However, with so many companies claiming to offer unmatched services, it can prove to be difficult to find the right one. In this article we will take a look at various tips to help you find the right CNC machining service.

Around 20 years ago machining workshops were pondering over whether they should switch over to CNC (Computer Numeric Controlled) from manual mills. Those who didn’t jump on the CNC bandwagon were eventually left behind . Today, the scenario for 5 axis milling and machining technology is somewhat similar. Many industries today, particularly those where a high degree of precision is required such as medical devices, optical equipment, aircraft, transport, aerospace and satellites have already turned to 5 axis technology as a way of speeding up manufacturing ability as well as increasing repeatable accuracy. The ability to produce complex machine parts offered by 5 axis machining allows for reduced labor time and tooling costs which lead to higher precision as well as lower costs per part. In this article we will take a look at the various advantages and benefits associated with 5 axis machining and why PRV Engineering invests and continues to invest in this technology on behalf of our clients.

Recent Comments