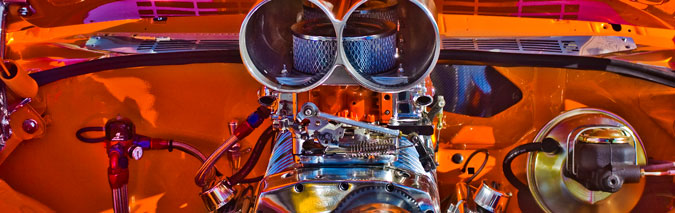

In the intricate machinery of the UK’s engineering sector, Automotive Powder Coating emerges as a vital cog, integral to the industry’s functionality and success. This innovative process has rapidly become a cornerstone in the manufacturing and finishing of automotive components, playing a pivotal role in enhancing both the performance and aesthetics of vehicles.

When it comes to finishing and cleaning operations, shot blasting is one of the most effective methods for surface treatment. It is a technological process used to remove various impurities from different surfaces using abrasives. In this article, we look at a few different shot blasting techniques, applications, and pros and cons with some additional FAQs at the end.

The term “fabrication” means to make something from raw materials whether it’s wood, plastic or certain types of metals. Several industries currently benefit from aluminium fabrication which refers mostly to the construction of metal structures. Choosing a material is a critical decision in all aspects of the production but so is the finishing process.

Although you can fabricate any metal, aluminium is considered one of the most common resulting in big demand for aluminium fabrication services across the world. It’s not surprising if you consider that aluminium is all around us in our homes and office buildings. Some of the most common are aluminium gates and aluminium frameworks used for doors, windows and even showers.

Shot blasting is used to clean, polish or strengthen metal preparing it for the application of overlays or specialist coatings. It is a technological process used to remove various impurities from different surfaces using abrasives. This includes removing rust or old layers of paint to prepare surfaces for further processing like painting, welding or powder coating. Many industries working with metal use shot blasting, including aerospace, automotive, construction, shipbuilding, rail among many others.

Finishing image of industrial spray painting Finishing any engineering job properly is just as important as any other operation along the production cycle. And by finishing the engineering job, we’re not talking about tidying the file and completing the invoicing. We are talking about the paint or powder coating finish to the product

The appearance of a finished product will always have an impact on the saleability. After all, if something looks rough and unfinished it’s less likely to sell. In addition, there’s the safety impact to consider. Rough edges and burrs can not only put buyers off but can be a serious health and safety risk. So an important part of finishing is to remove those risks.

- 1

- 2

Recent Comments