Developing ultra-high-strength alloys is a challenging task as it often ends up exposing weaknesses in other areas. Creating super steel requires a fine balance between all the different properties and a breakthrough has emerged, defying convention.

The construction industry has evolved significantly with many new and improved methods such as structural steel fabrication. This process, along with welding, is demanding and you should only consult experienced fabricators as it requires expert knowledge, skills and resources.

For a successful project, from manufacturing structural steel beams and steel balustrades to components and equipment, every good fabricator should follow a specific process. A less experienced company may not be able to perform the necessary tasks which could compromise product viability.

Metal fabrication refers to processes involving cutting, shaping or moulding a raw material (metal) into a final product. Metal components are available in a wide variety of dimensions and materials such as sheet metal, metal rods and metal bars. The metal fabrication process involves a wide range of skills and disciplines from profiling, bending and forming, cropping, coded welding to assembly and painting.

It is, without a doubt, a specialist process that requires expertly trained staff and advanced machinery. Coincidentally, those are also the two main factors to consider when looking for a trusted engineering company. While modern technology, machinery and computer aided design software have pushed fabrication services to the next level, there is no substitute for experience.

The construction industry has evolved significantly and with it, many new and improved methods including steel fabrication. If you think about skyscrapers, warehouses and shopping malls, almost every aspect in construction consists of structural steel. Steel framed structures are common across many construction projects including garages, residential properties and short-term temporary structures.

Steel fabrication is used to create various components and products with different qualities for different applications. Fact is, structural steelwork has been the primary choice for most builders, engineers, contractors and structural steel fabricators. Many industries rely on steel fabrication because of the quality, reliability, flexibility, cost effectiveness and sustainability that it offers.

Structural steel fabrication involves a complex process of turning steel into fabricated products for a construction project or other industrial applications. Structural steel has been a first choice in all types of construction and for quite some time. Even the smallest project incorporates steel because it offers faster construction among many other benefits.

The structural steel fabrication and welding process is demanding and you should only consult experienced fabricators. A less experienced company may not be able to properly perform the tasks at hand which means they could compromise the product viability. Welding and fabricating structural steel requires special expertise that only a few companies share, PRV Engineering is right up there.

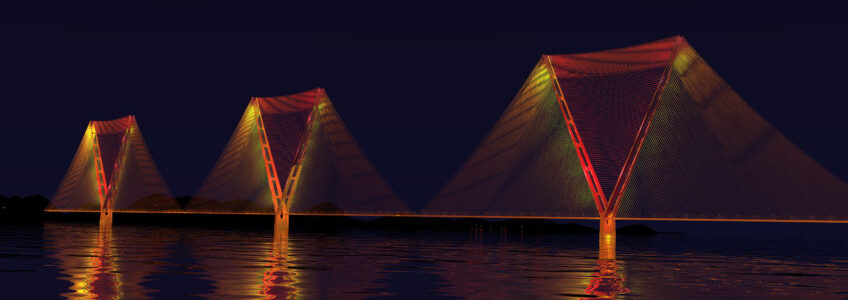

The world of construction and technology is advancing at a rapid pace achieving what no-one thought possible only a few years ago. A split-pylon concept bridge is the focus of an EPSRC-funded project at Sheffield and Brunel University. Partnering with a long span bridge expert, Ian Firth, the team of UK engineers used mathematical modelling techniques to identify new bridge designs. They claim that it could beat the current record of a 2 km single span bridge.

Newly identified bridge structures could allow for the construction of significantly longer bridges in the near future. The possibility to make a crossing over the Strait of Gibraltar, from the Iberian Peninsula to Morocco is very real.

The word “fabrication” means to make something from raw material. Steel fabrication is no different and plays an extremely important role in the world’s infrastructure and economy. Practically every aspect of our civilization benefits from some form of fabricated metal. From household appliances to vehicles and parts, our lives would be unrecognisable without carbon steel, stainless steel and aluminium.

Although the construction of steel buildings dates back to the 20th century, they became more popular during World War II. Thereafter, steel buildings expanded significantly once steel became more readily available. Modern technology, machinery and computer aided design software have pushed steel fabrication to the next level as we see it today. Steel fabrication now involves the implementation of various manufacturing processes including bending, cutting, grinding, brazing and welding.

The latest monthly CBI Industrial Trends Survey reports that UK Manufacturing output looks promising. They suggest that output has increased strongly and faster since the end of 2017. According to CBI, growth was broad-based, with output increasing in 14 out of 17 sub-sectors. Among the top performers are food, drink and tobacco and mechanical engineering.

Total order books show similar, healthy levels resembling that of December 2017. Exports remained stable, well above average and in line with the past 16 months. Output price expectations for inflation softened to the weakest in almost a year while stock levels moved below average. It hasn’t been smooth sailing as the UK Manufacturing sector faced some serious challenges.

While the CBI believes manufacturers will continue to benefit from robust external demand and the lower exchange rate, overall economic growth is expected to remain subdued. This comes as a result of weak consumer income growth and the continuous uncertainty stemming investments.

Recent Comments